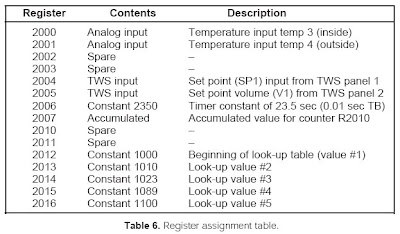

The assignment of addresses to the registers used in the control program is another important aspect of PLC organization. The easiest way to assign registers is to list all of the available PLC registers. Then, as they are used, describe each register’s contents, description, and function in a register assignment table. Table 6 shows a register assignment table for the first 15 registers in a PLC system, ranging from address 2000(8) to address 2016(8)

ELEMENTS TO LEAVE HARDWIRED

During the assignment of inputs and outputs, the user should decide which devices will not be wired to the controller. These elements will remain part of the electromechanical control logic. These elements usually include devices that are not frequently switched off after start, such as compressors and hydraulic pumps. Components like emergency stops and master start push buttons should also remain hardwired, principally for safety purposes. This way, if the controller is faulty and an emergency occurs, the user can shut down the system without PLC intervention.

Figure 10 provides an example of system components that are typically left hardwired. Note that the normally open PLC Fault Contact 1 (or watchdog timer contact) is wired in series with other emergency conditions. This contact stays closed when the controller is operating correctly, but opens when a fault occurs. The system designer can also use this contact if an emergency occurs to disable the PLC system’s operation. PLC fault contacts are safety contacts that are available to the user when implementing or enhancing a safety circuit. When a PLC is operating correctly, the normally open fault contact closes and the normally closed one opens when the PLC is first turned on. As shown in Figure 10, these contacts are connected in series with the hardwired circuit, so that if the PLC fails during standard operation, the normally open contacts will open. This will shut down the hardwired circuit at the point where the PLC becomes the controlling element. This circuit also uses a safety control relay (SCR) to control power to the rest of the control components. The normally closed fault contacts are used to indicate an alarm condition.

In the diagram shown in Figure 10, an emergency situation (including a PLC malfunction) will remove power (L1) to the I/O modules. The turning OFF of the safety control relay (SCR) will open the SCR contact, stopping the flow of power to the system. Furthermore, the normally closed PLC fault contact (PLC Fault Contact 2) in the hardwired section will alert personnel of a system failure due to a PLC malfunction. The designer should implement this type of alarm in the main PLC rack, as well as in each remote I/O rack location, since remote systems also have fault contacts incorporated into the remote controllers. This allows subsystem failures to be signaled promptly, so that the problem can be fixed without endangering personnel.

No comments:

Post a Comment